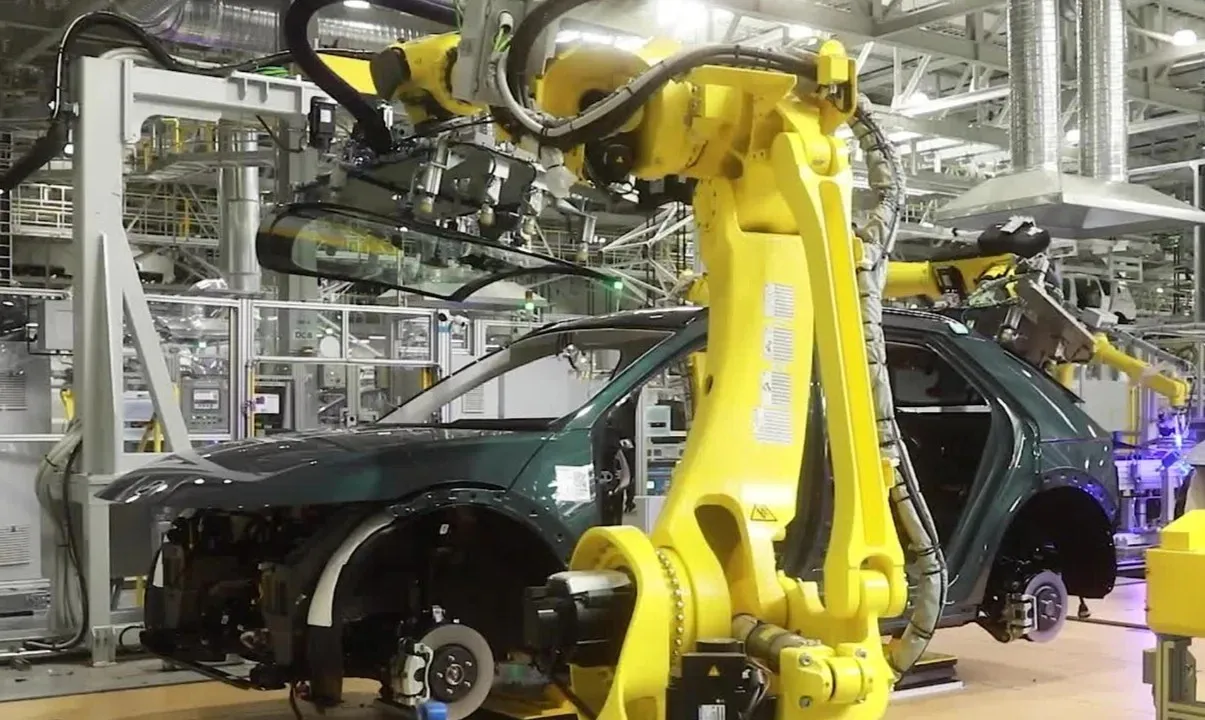

Hyundai’s newest factory in Georgia is being called one of the most advanced auto plants in the world. The $7.6 billion Metaplant America facility opened its doors in late 2024, designed to produce electric vehicles at an enormous scale. What makes it stand out is the way the company has filled the plant with robots. Hundreds of robotic arms and automated vehicles carry out jobs once done by humans. Yet, despite the technology, Hyundai says workers are still the backbone of this futuristic factory.

A Factory Where Robots Do the Heavy Lifting

Walking through the plant feels like stepping into the future. Robots weld steel frames, carry parts across the floor, and even install doors on cars something no other factory in the world has fully automated before. Industry watchers call it a major leap in manufacturing. But the human workforce is still a big part of the picture. About 1,450 employees currently work at the site. That’s a very different ratio compared to older U.S. auto factories, where there are usually many more people for each robot.

Why People Can’t Be Replaced

Robots may be fast and precise, but there are things they can’t quite do. Workers at Hyundai’s Georgia plant handle delicate details like fitting trim pieces, checking paint surfaces, and making adjustments that require judgment and a human touch. One worker told The Wall Street Journal that the small imperfections in car panels need trained eyes and steady hands to fix something a robot can’t yet handle. Hyundai’s executives agree, saying they don’t see automation as a way to cut people out, but as a way to let them focus on more skilled tasks.

Hyundai’s Big Bet on the U.S.

This plant is part of a much larger strategy. Hyundai plans to invest more than $21 billion in the U.S. over the next few years, focusing on electric vehicles and battery production. Once fully operational, the Georgia facility is expected to build up to 500,000 cars a year and create thousands more jobs in the region.

The company is also looking ahead to the next phase of automation. Hyundai owns Boston Dynamics and plans to deploy Atlas humanoid robots in the future. These machines are designed to carry heavy parts and perform more complex jobs. Still, company leaders admit that people will remain central to the assembly process.

Where Robots Fall Short

Even with advanced systems, automation has its limits. Robots still struggle with flexible materials like fabric, wiring, or upholstery. They also can’t easily adapt to unexpected problems that arise on the assembly line. Final quality checks, for example, are still entirely human. Cars must be test-driven and inspected before leaving the plant, and Hyundai says customers feel more confident knowing real people are behind those final decisions.

Finding Balance Between People and Technology

The story of Hyundai’s new Georgia plant isn’t about replacing workers. it’s about balance. Robots are taking over repetitive, dangerous, and physically demanding tasks, while people step in where intuition and adaptability are required. It’s a model that many industry experts believe will define the future of car manufacturing in America. For now, one thing is clear no matter how advanced the robots get, the auto industry still runs best when humans are part of the equation.